Abstract

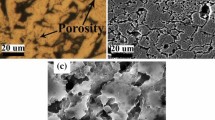

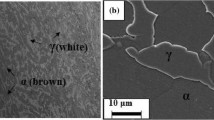

Super duplex stainless steel (SDSS) has excellent corrosion resistance and good mechanical properties. However, the tribological characteristics of these steels reduce their applicability. Plasma nitriding (PN) and cathodic cage deposition (CCPD) have been used to cause surface changes to improve wear resistance without significant loss of corrosion resistance. In this study, PN and CCPD treatments were performed at 350 and 450 °C to evaluate the influence of temperature on wear and corrosion resistance. Microhardness, XRD, SEM, wear, and corrosion tests were performed to evaluate the results. It was observed that the treatments adopted in the study improved the hardness and wear resistance of all samples. The results showed that nitriding performed well in terms of corrosion resistance at low temperatures (350 °C), while at higher temperatures (450 °C), the duplex treatment proved to be more suitable.

Similar content being viewed by others

References

F.M.R. Borges, W.F.A. Borges, R.L.P. Santos, V.S. Leal, J.R. dos Santos Júnior, A.O. Lobo, and R.R.M. de Sousa, Corrosion Resistance and Microstructural Evaluation of a Plasma Nitrided Weld Joint of UNS S32750 Super Duplex Stainless Steel, Mat. Res., 2021, 6, p 45614. https://doi.org/10.1590/1980-5373-MR-2021-0087

G.S. da Fonseca, P.M. de Oliveira, M.G. Diniz, D.V. Bubnoff, and J.A. de Castro, Sigma Phase in Superduplex Stainless Steel: Formation, Kinetics and Microstructural Path, Mat. Res., 2017, 20, p 249–255.

D. Martínez, R. Gonzalez, K. Montemayor, A. Juarez-Hernandez, G. Fajardo, and M.A.L. Hernandez-Rodriguez, Amine Type Inhibitor Effect on Corrosion-Erosion Wear in Oil Gas Pipes, Wear, 2009, 267(1), p 255–258.

R. Barker, X. Hu, A. Neville, and S. Cushnaghan, Empirical Prediction of Carbon-Steel Degradation Rates on an Offshore Oil and Gas Facility: Predicting CO2 Erosion-Corrosion Pipeline Failures Before They Occur, SPE J., 2013, 19(03), p 425–436.

A.B. Tahchieva, N. Llorca-Isern, and J.-M. Cabrera, Duplex and Superduplex Stainless Steels: Microstructure and Property Evolution by Surface Modification Processes, Metals, 2019, 9(3), p 347.

Y.S. Sato, T.W. Nelson, C.J. Sterling, R.J. Steel, and C.-O. Pettersson, Microstructure and Mechanical Properties of Friction Stir Welded SAF 2507 Super Duplex Stainless Steel, Mater. Sci. Eng., A, 2005, 397(1), p 376–384.

F. Borgioli, The “Expanded” Phases in the Low-Temperature Treated Stainless Steels: A Review, Metals, 2022, 12(2), p 331.

Z. Schulz, P. Whitcraft, and D. Wachowiak Availability and Economics of Using Duplex Stainless Steels. (Texas, USA), OnePetro, 2014, https://onepetro.org/NACECORR/proceedings/CORR14/All-CORR14/NACE-2014-4345/123141

M. Snis and J. Olsson, Reduce Costs for Storage and Distribution of Desalted Water — Use Duplex Stainless Steel, Desalination, 2008, 223(1), p 476–486.

R. Abdolvand, M. Atapour, and M. Shamanian, Effects of Cooling Regimes on the Microstructural and Mechanical Properties of the Transient Liquid Phase Joints of UNS S32750 Super Duplex Stainless Steel/BNi-2/AISI 304 Stainless Steel, J Mater Sci, 2022, 57(6), p 4383–4398.

S. Saravanan, K. Raghukandan and N. Sivagurumanikandan, Pulsed Nd: YAG Laser Welding and Subsequent Post-Weld Heat Treatment on Super Duplex Stainless Steel, J. Manuf. Process., 2017, 25, p 284–289.

M.F. McGuire, “Stainless Steels for Design Engineers”, (USA), ASM International, New York, 2008.

C.B. von der Ohe, R. Johnsen, and N. Espallargas, Multi-Degradation Behavior of Austenitic and Super Duplex Stainless Steel – The Effect of 4-Point Static and Cyclic Bending Applied to a Simulated Seawater Tribocorrosion System, Wear, 2012, 288, p 39–53.

M.Z. Babur, Z. Iqbal, M. Shafiq, M.Y. Naz, and M.M. Makhlouf, Hybrid TiN-CCPN Coating of AISI-201 Stainless Steel by Physical Vapor Deposition Combined with Cathodic Cage Plasma Nitriding for Improved Tribological Properties, J. Build. Eng., 2022, 45, p 103512.

A.M.S. Dias, E.C. Silva, and M.S. Libório, Experimental-Numerical Technique to Evaluate the Thickness of TiN Thin Film, Mat. Res., 2019, 22, p 4561. https://doi.org/10.1590/1980-5373-MR-2018-0283

M. Tsujikawa, D. Yoshida, N. Yamauchi, N. Ueda, T. Sone, and S. Tanaka, Surface Material Design of 316 Stainless Steel by Combination of Low Temperature Carburizing and Nitriding, Surf. Coat. Technol., 2005, 200(1), p 507–511.

J. Wang, Y. Lin, D. Zeng, J. Yan, and H. Fan, Effects of the Process Parameters on the Microstructure and Properties of Nitrided 17–4PH Stainless Steel, Metall. Mater. Trans. B, 2013, 44(2), p 414–422.

E. de Araújo, R.M. Bandeira, M.D. Manfrinato, J.A. Moreto, R. Borges, S.S. Vales, P.A. Suzuki, and L.S. Rossino, Effect of Ionic Plasma Nitriding Process on the Corrosion and Micro-Abrasive Wear Behavior of AISI 316L Austenitic and AISI 470 Super-Ferritic Stainless Steels, J. Mater. Res. Technol., 2019, 8(2), p 2180–2191.

H.-J. Spies, C. Eckstein, and H. Zimdars, Structure and Corrosion Behaviour of Stainless Steels after Plasma and Gas Nitriding, Surf. Eng., 2002, 18(6), p 459–460.

G.M. Michal, F. Ernst, H. Kahn, Y. Cao, F. Oba, N. Agarwal, and A.H. Heuer, Carbon Supersaturation Due to Paraequilibrium Carburization: Stainless Steels with Greatly Improved Mechanical Properties, Acta Mater., 2006, 54(6), p 1597–1606.

F.N. Jespersen, J.H. Hattel, and M.A.J. Somers, Modelling the Evolution of Composition-and Stress-Depth Profiles in Austenitic Stainless Steels during Low-Temperature Nitriding, Modelling Simul, Mater. Sci. Eng., 2016, 24(2), p 025003.

M.G.C. Barbosa, B.C. Viana, F.E.P. Santos, F. Fernandes, M.C. Feitor, T.H.C. Costa, M. Naeem, and R.R.M. Sousa, Surface Modification of Tool Steel by Cathodic Cage TiN Deposition, Surf. Eng., 2021, 37(3), p 334–342.

E.S. Costa, R.R.M. de Sousa, R.M. Monção, M.S. Libório, and T.H.C. Costa, Plasma Nitriding and Deposition in AISI M2 and D2 Steel Tools Used in Nail Forming and Stam**: A Viability Study, Matér. Rio J., 2021, 26, p 456. https://doi.org/10.1590/S1517-707620210001.1222

O. Gokcekaya, C. Ergun, T. Gulmez, T. Nakano, and S. Yilmaz, Structural Characterization of Ion Nitrided 316L Austenitic Stainless Steel: Influence of Treatment Temperature and Time, Metals, 2022, 12(2), p 306.

L. Gil, S. Brühl, L. Jiménez, O. Leon, R. Guevara, and M.H. Staia, Corrosion Performance of the Plasma Nitrided 316L Stainless Steel, Surf. Coat. Technol., 2006, 201(7), p 4424–4429.

E. Roliński, Effect of Plasma Nitriding Temperature on Surface Properties of Austenitic Stainless Steel, Surf. Eng., 1987, 3(1), p 35–40.

A. Nishimoto and K. Nakazawa, Effect of Sample Mount on Active Screen Plasma Duplex Processing, Mater. Sci. Forum Trans. Tech. Publ. Ltd, 2014, 782, p 16–22.

M. Ossowski, T. Borowski, M. Tarnowski, and T. Wierzchon, Cathodic Cage Plasma Nitriding of Ti6Al4V Alloy, Mater. Sci., 2016, 22(1), p 25–30.

L.C. Silva, M.S. Libório, L.L.F. Lima, R.R.M. Sousa, T.H.C. Costa, M. Naeem, D.A.P. Reis, P.A. Radi, and S.M. Alves, Deposition of MoS2-TiN Multilayer Films on 1045 Steel to Improve Common Rail Injection System, J. Mater. Eng. Perform., 2020, 29(10), p 6740–6747.

R.F. Lopes, J.A.P. da Costa, W. Silva, B.C. Viana, F.R. Marciano, A.O. Lobo, and R.R.M. Sousa, TiO2 Anti-Corrosive Thin Films on Duplex Stainless Steel Grown Using Cathodic Cage Plasma Deposition, Surf. Coat. Technol., 2018, 347, p 136–141.

A.G.F. Araújo, M. Naeem, L.N.M. Araújo, T.H.C. Costa, K.H. Khan, J.C. Díaz-Guillén, J. Iqbal, M.S. Liborio, and R.R.M. Sousa, Design, Manufacturing and Plasma Nitriding of AISI-M2 Steel Forming Tool and Its Performance Analysis, J. Mater. Res., 2020, 9(6), p 14517–14527.

E. Broitman, Indentation Hardness Measurements at Macro- Micro-, and Nanoscale: A Critical Overview, Tribol Lett, 2016, 65(1), p 23.

M. Jamil, N. He, X. Huang, W. Zhao, M.K. Gupta, and A.M. Khan, Measurement of Machining Characteristics under Novel Dry Ice Blasting Cooling Assisted Milling of AISI 52100 Tool Steel, Measurement, 2022, 191, p 110821.

H.S. Silva, F.R. Marciano, A.S. de Menezes, T.H.C. Costa, L.S. Almeida, L.S. Rossino, I.O. Nascimento, R.R.M. Sousa, and B.C. Viana, Morphological Analysis of the TiN Thin Film Deposited by CCPN Technique, J. Mater. Res. Technol., 2020, 9(6), p 13945–13955.

P.R.Q. de Almeida, P.L.C. Serra, M.R. Danelon, L.S. Rossino, T.H.C. Costa, M.C. Feitor, A.S. de Menezes, R.M. Nascimento, R.M. Sousa, and F.R. Marciano, Plasma Duplex Treatment Influence on the Tribological Properties of the UNS S32760 Stainless Steel, Surf. Coat. Technol., 2021, 426, p 127774.

A.G.F. Araújo, M. Naeem, L.N.M. Araújo, M.S. Libório, M.R. Danelon, R.M. Monção, L.S. Rossino, M.C. Feitor, and R.M. do Nascimento, T.H.C. Costa, and R.R.M. Sousa, Duplex Treatment with Hastelloy Cage on AISI 5160 Steel Cutting Tools, Mater. Sci. Technol., 2022, 38(8), p 499–506.

R.M. Monção, M.R. Danelon, L.S. Almeida, L.S. Rossino, F.R. Marciano, T.H.C. Costa, M.C. Feitor, R.M. Nascimento, and R.R.M. Sousa, Molybdenum Oxide Coatings Deposited on Plasma Nitrided Surfaces, Mat. Res., 2022 https://doi.org/10.1590/1980-5373-MR-2021-0469

R.C. Cozza, Estudo da obtenção do Regime Permanente de Desgaste em ensaios de desgaste micro-abrasivo por esfera rotativa conduzidos em corpos-de-prova de WC-Co P20 e aço-ferramenta M2, Matéria Rio J., 2018 https://doi.org/10.1590/S1517-707620170001.0322

R.I. Trezona, D.N. Allsopp, and I.M. Hutchings, Transitions between Two-Body and Three-Body Abrasive Wear: Influence of Test Conditions in the Microscale Abrasive Wear Test, Wear, 1999, 225–229, p 205–214.

S. Ichimura, S. Takashima, I. Tsuru, D. Ohkubo, H. Matsuo, and M. Goto, Application and Evaluation of Nitriding Treatment Using Active Screen Plasma, Surf. Coat. Technol., 2019, 374, p 210–221.

M.S. Libório, E.O. Almeida, S.M. Alves, T.H.C. Costa, M.C. Feitor, R.M. Nascimento, R.R.M. Sousa, M. Naeem, and M. Jelani, Enhanced Surface Properties of M2 Steel by Plasma Nitriding Pre-Treatment and Magnetron Sputtered TiN Coating, Int. J. Surf. Sci. Eng., 2020, 14(4), p 288–306.

Y.E. Núñez de la Rosa, O. Palma Calabokis, P.C. Borges, and V. Ballesteros Ballesteros, Effect of Low-Temperature Plasma Nitriding on Corrosion and Surface Properties of Duplex Stainless Steel UNS S32205, J. Mater. Eng. Perform, 2020, 29(4), p 2612–2622.

O. Palma Calabokis, Y. Núñez de la Rosa, C.M. Lepienski, R. Perito Cardoso, and P.C. Borges, Crevice and Pitting Corrosion of Low Temperature Plasma Nitrided UNS S32750 Super Duplex Stainless Steel, Surf. Coat. Technol., 2021, 413, p 127095.

J.O. Pereira Neto, R.O. da Silva, E.H. da Silva, J.A. Moreto, R.M. Bandeira, M.D. Manfrinato, and L.S. Rossino, Wear and Corrosion Study of Plasma Nitriding F53 Super Duplex Stainless Steel, Mat. Res., 2016, 19, p 1241–1252.

W.R. de Oliveira, B.C.E.S. Kurelo, D.G. Ditzel, F.C. Serbena, C.E. Foerster, and G.B. de Souza, On the S-Phase Formation and the Balanced Plasma Nitriding of Austenitic-Ferritic Super Duplex Stainless Steel, Appl. Surf. Sci., 2018, 434, p 1161–1174.

J. Olsson and M. Snis, Duplex — A New Generation of Stainless Steels for Desalination Plants, Desalination, 2007, 205(1), p 104–113.

R.A. Andrade and R. Magnabosco, Computational Simulation of Duplex Stainless Steel Continuous Cooling Transformation Curves Using DICTRA®, Mat. Res., 2022 https://doi.org/10.1590/1980-5373-MR-2021-0593

D.K. Prajapati and M. Tiwari, The Correlation between Friction Coefficient and Areal Topography Parameters for AISI 304 Steel Sliding against AISI 52100 Steel, Friction, 2021, 9(1), p 41–60.

M.S. Libório, G.B. Praxedes, L.L.F. Lima, I.G. Nascimento, R.R.M. Sousa, M. Naeem, T.H. Costa, S.M. Alves, and J. Iqbal, Surface Modification of M2 Steel by Combination of Cathodic Cage Plasma Deposition and Magnetron Sputtered MoS2-TiN Multilayer Coatings, Surf. Coat. Technol., 2020, 384, p 125327.

Funding

This study was financed in part by the Coordenação de Aperfeiçoamento de Pessoal de Nível Superior—Brasil (CAPES)—Finance Code 001.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

No potential conflict of interest was reported by the author(s).

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Silva, L.G.L., Naeem, M., Costa, T.H.C. et al. Wear and Corrosion of UNS S32750 Steel Subjected to Nitriding and Cathodic Cage Deposition. J. of Materi Eng and Perform 32, 9011–9018 (2023). https://doi.org/10.1007/s11665-022-07792-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-022-07792-3