Abstract

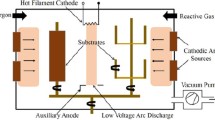

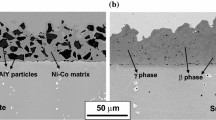

NiCoCrAlY coatings have good corrosion and oxidation resistance in gas turbine blades at elevated temperatures. This study used the cathodic arc evaporation physical vapor deposition technique to apply the coatings on a Mar-M-200 nickel superalloy. The impact of a negative substrate bias voltage (0-300 V) and subsequent vacuum heat treatment on the microstructure, morphology, and phase transformation were investigated using EDX, EPMA, XRD, and SEM equipment. To evaluate the hot corrosion behavior of specimens, average mass change of substrate and coatings were considered in a mixture of Na2SO4-25 wt.% K2SO4 salt at 950 °C. Based on experimental results, the main phases at lower biases of 0 V and − 120 V were γ′-NI3Al, γ-Ni, and α-Co. In contrast, higher negative bias voltages revealed sharper and more substantial diffraction peaks of the α-Cr and β-(Co, Cr)Al phases were revealed at. In floating conditions (0 V bias), the average crystallite size of samples was approximately 26 nm. The crystallite sizes were increased by enhancing the bias voltage up to − 300 V. The heat treatment of coatings achieves lower porosity and a smoother surface due to diffusion and annealing effects. Furthermore, heat-treated samples demonstrated larger crystallites. The EDS analysis revealed that the heat-treated specimens contained more Al and Y elements and lower Ni, Co, and Cr elements than the as-deposited specimens. After 30 h, the heat-treated coated sample at − 300 V bias exhibited only a short weight increment of 3.69 mg/cm2 and showed the highest corrosion resistance against hot corrosion of all specimens.

Similar content being viewed by others

References

J. Vetter, MCrAlY Coatings Deposited by Cathodic Vacuum Arc Evaporation, J. Adv. Mater., 1994, 31(2), p 41–47.

K. Yuan, R. Eriksson, R. Lin Peng, X.H. Li, S. Johansson, and Y.D. Wang, MCrAlY Coating Design Based on Oxidation-Diffusion Modelling. Part I: Microstructural Evolution, Surf. Coat. Technol., 2014, 254, p 79–96. https://doi.org/10.1016/j.surfcoat.2014.05.067

Y. Zhang, B. Bates, J. Steward, and S. Dryepondt, Oxidation and Hot Corrosion Performance of NiCoCrAlY Coatings Fabricated Via Electrolytic Codeposition, Oxid. Met., 2019, 91(1–2), p 95–112. https://doi.org/10.1007/s11085-018-9868-z

J. Lu, S. Zhu, and F. Wang, High Temperature Corrosion Behavior of an AIP NiCoCrAlY Coating Modified by Aluminizing, Surf. Coat. Technol., 2011, 205(21–22), p 5053–5058. https://doi.org/10.1016/j.surfcoat.2011.05.005

J. Shi, T. Zhang, B. Sun, B. Wang, X. Zhang, and L. Song, Isothermal Oxidation and TGO Growth Behavior of NiCoCrAlY-YSZ Thermal Barrier Coatings on a Ni-Based Superalloy, J. Alloys Compd., 2020, 844, p 156093. https://doi.org/10.1016/j.jallcom.2020.156093

J.H. Lee, P.C. Tsai, and J.W. Lee, Cyclic Oxidation Behavior and Microstructure Evolution of Aluminized, Pt-Aluminized High Velocity Oxygen Fuel Sprayed CoNiCrAlY Coatings, Thin Solid Films, 2009, 517(17), p 5253–5258. https://doi.org/10.1016/j.tsf.2009.03.148

M.H. Khajezadeh, M. Mohammadi, and M. Ghatee, Hot Corrosion Performance and Electrochemical Study of CoNiCrAlY/YSZ/YSZ-La2O3 Multilayer Thermal Barrier Coatings in the Presence of Molten Salt, Mater. Chem. Phys., 2018, 220(June), p 23–34. https://doi.org/10.1016/j.matchemphys.2018.08.004

A. Shamsipoor, M. Farvizi, M. Razavi, A. Keyvani, B. Mousavi, and W. Pan, Hot Corrosion Behavior of Thermal Barrier Coating on Cr2AlC and CoNiCrAlY Substrates at 950°C in Presence of Na2SO4+V2O5 Molten Salts, Surf. Interfaces, 2020, 21(July), p 1679. https://doi.org/10.1016/j.surfin.2020.100679

A. Feizabadi, M. Salehi Doolabi, S.K. Sadrnezhaad, and M. Rezaei, Cyclic Oxidation Characteristics of HVOF Thermal-Sprayed NiCoCrAlY and CoNiCrAlY Coatings at 1000 °C, J. Alloys Compd., 2018, 746, p 509–519. https://doi.org/10.1016/j.jallcom.2018.02.282

R. Goyal and K. Goyal, Development of CNT Reinforced Al2O3-TiO2 Coatings for boiler Tubes to Improve Hot Corrosion Resistance, J. Electrochem. Sci. Eng., 2022, 12(5), p 937–945. https://doi.org/10.5599/jese.1291

M.S. Reddy, C.D. Prasad, P. Patil, M.R. Ramesh, and N. Rao, Hot Corrosion Behavior of Plasma-Sprayed NiCrAlY/TiO2 and NiCrAlY/Cr2O3/YSZ Cermets Coatings on Alloy Steel, Surf. Interfaces, 2021, 22(2020), p 1810. https://doi.org/10.1016/j.surfin.2020.100810

G.W. Goward, Progress in Coatings for Gas Turbine Airfoils, Surf. Coat. Technol., 1998, 108–109(1–3), p 73–79. https://doi.org/10.1016/S0257-8972(98)00667-7

G. Pulci et al., High Temperature Oxidation of MCrAlY Coatings Modified by Al2O3 PVD Overlay, Surf. Coat. Technol., 2015, 268, p 198–204. https://doi.org/10.1016/j.surfcoat.2014.09.048

M. Shen, P. Zhao, Y. Gu, S. Zhu, and F. Wang, High Vacuum Arc Ion Plating NiCrAlY Coatings: Microstructure and Oxidation Behavior, Corros. Sci., 2015, 94, p 294–304. https://doi.org/10.1016/j.corsci.2015.02.032

A. Raffaitin, F. Crabos, E. Andrieu, and D. Monceau, Advanced Burner-Rig Test for Oxidation-Corrosion Resistance Evaluation of MCrAlY/Superalloys Systems, Surf. Coat. Technol., 2006, 201(7 Spec Iss), p 3829–3835. https://doi.org/10.1016/j.surfcoat.2006.07.256

M. Elsa, M. Frommherz, A. Scholz, and M. Oechsner, Interdiffusion in MCrAlY Coated Nickel-Base Superalloys, Surf. Coat. Technol., 2016, 307(Part A), p 565–573. https://doi.org/10.1016/j.surfcoat.2016.09.049

F. Ghadami, A. Sabour Rouh Aghdam, A. Zakeri, B. Saeedi, and P. Tahvili, Synergistic Effect of CeO2 and Al2O3 Nanoparticle Dispersion on the Oxidation Behavior of MCrAlY Coatings Deposited by HVOF, Ceram. Int., 2020, 46(4), p 4556–4567. https://doi.org/10.1016/j.ceramint.2019.10.184

A.B. Elshalakany, T.A. Osman, W. Hoziefa, A.V. Escuder, and V. Amigó, Comparative Study Between High-Velocity Oxygen Fuel and Flame Spraying Using MCrAlY Coats on a 304 Stainless Steel Substrate, J. Mater. Res. Technol., 2019, 8(5), p 4253–4263. https://doi.org/10.1016/j.jmrt.2019.07.035

V.P.S. Sidhu, K. Goyal, and R. Goyal, Comparative Evaluation of Hot Corrosion Resistance of 83WC–17CO and 86WC–10CO–4Cr Coatings on Some Boiler Steels in Actual Boiler in Thermal Power Plant, Metallogr. Microstruct. Anal., 2017, 6(6), p 512–518. https://doi.org/10.1007/s13632-017-0392-3

S.G. Wang, X. De Bai, B.C. Wang, and Y.D. Fan, The Positive Roles of Metallic Droplets in Deposition of Alloy Films by Cathodic Arc Plasma Deposition, J. Mater. Res., 1996, 11(5), p 1137–1143. https://doi.org/10.1557/JMR.1996.0146

S. Cao et al., Influence of Composition and Microstructure on the Tribological Property of SPS Sintered MCrAlY Alloys at Elevated Temperatures, J. Alloys Compd., 2018, 740, p 790–800. https://doi.org/10.1016/j.jallcom.2017.12.233

J. Cai et al., Hot Corrosion Behaviour of Thermally Sprayed CoCrAlY Coating Irradiated by High-Current Pulsed Electron Beam, J. Alloys Compd., 2019, 784, p 1221–1233. https://doi.org/10.1016/j.jallcom.2019.01.071

X. Hou, C. Zhang, F. Wang, and G. Ding, Fabrication and Characterization of NiCoCrAlY Coating Deposited on Nickel-Based Superalloy Substrates, Vacuum, 2018, 155, p 55–59. https://doi.org/10.1016/j.vacuum.2018.05.041

H. Peng, H. Guo, J. He, and S. Gong, Oxidation and Diffusion Barrier Behaviors of Double-Layer NiCoCrAlY Coatings Produced by Plasma Activated EB-PVD, Surf. Coat. Technol., 2011, 205(19), p 4658–4664. https://doi.org/10.1016/j.surfcoat.2011.04.017

X. Peng, S. Jiang, J. Gong, X. Sun, and C. Sun, Preparation and Hot Corrosion Behavior of a NiCrAlY + AlNiY Composite Coating, J. Mater. Sci. Technol., 2016, 32(6), p 587–592. https://doi.org/10.1016/j.jmst.2016.04.017

J. Wang et al., Hot Corrosion of Arc Ion Plating NiCrAlY and Sputtered Nanocrystalline Coatings on a Nickel-Based Single-Crystal Superalloy, Corros. Sci., 2017, 123(April), p 27–39. https://doi.org/10.1016/j.corsci.2017.04.004

P. Zhao, M. Shen, Y. Gu, S. Zhu, and F. Wang, Oxidation Behavior of NiCrAlY Coatings Prepared by Arc Ion Plating Using Various Substrate Biases: Effects of Chemical Composition and Thickness of the Coatings, Corros. Sci., 2017, 126(December 2016), p 317–323. https://doi.org/10.1016/j.corsci.2017.07.014

Y.N. Wu et al., Evaluation of Arc Ion Plated NiCoCrAlYSiB Coatings After Oxidation at 900–1100 °C, Surf. Coat. Technol., 2006, 200(9), p 2857–2863. https://doi.org/10.1016/j.surfcoat.2005.04.055

S.C. Vettivel, R. Jegan, J. Vignesh, and S. Suresh, Surface Characteristics and Wear Depth Profile of the TiN, TiAlN and AlCrN Coated Stainless Steel in Dry Sliding Wear Condition, Surf. Interfaces, 2017, 6, p 1–10. https://doi.org/10.1016/j.surfin.2016.10.008

K. Yuan, R. Lin Peng, X.H. Li, S. Johansson, and Y.D. Wang, Some Aspects of Elemental Behaviour in HVOF MCrAlY Coatings in High-Temperature Oxidation, Surf. Coat. Technol., 2015, 261, p 86–101. https://doi.org/10.1016/j.surfcoat.2014.11.053

Z.B. Bao et al., Preparation and Hot Corrosion Behaviour of an Al-Gradient NiCoCrAlYSiB Coating on a Ni-Base Superalloy, Corros. Sci., 2009, 51(4), p 860–867. https://doi.org/10.1016/j.corsci.2009.01.003

S.M. Jiang et al., Preparation and Hot Corrosion Behaviour of a MCrAlY + AlSiY Composite Coating, Corros. Sci., 2008, 50(11), p 3213–3220. https://doi.org/10.1016/j.corsci.2008.08.018

F. Movassagh-Alanagh and M. Mahdavi, Improving Wear and Corrosion Resistance of AISI 304 Stainless Steel by a Multilayered Nanocomposite Ti/TiN/TiSiN Coating, Surf. Interfaces, 2020, 18, p 100428. https://doi.org/10.1016/j.surfin.2019.100428

P.M. Samim, A. Fattah-alhosseini, H. Elmkhah, O. Imantalab, and M. Nouri, A Study on Comparing Surface Characterization and Electrochemical Properties of Single-Layer CrN Coating with Nanostructured Multilayer ZrN/CrN Coating in 3.5 wt.% NaCl Solution, Surf. Interfaces, 2020, 21(August), p 100721. https://doi.org/10.1016/j.surfin.2020.100721

S. **e et al., Effect of Bias Voltage on the Oxidation Resistance of NiCoCrAlYTa Coatings Prepared by Arc Ion Plating, Corros. Sci., 2019, 147(December), p 330–341. https://doi.org/10.1016/j.corsci.2018.11.030

R. Lan, C. Wang, Z. Ma, G. Lu, P. Wang, and J. Han, Effects of Arc Current and Bias Voltage on Properties of AlCrN Coatings by Arc Ion Plating with Large Target, Mater. Res. Express, 2019 https://doi.org/10.1088/2053-1591/ab5140

J.C. Ding, Q.M. Wang, Z.R. Liu, S. Jeong, T.F. Zhang, and K.H. Kim, Influence of Bias Voltage on the Microstructure, Mechanical and Corrosion Properties of AlSiN Films Deposited by HiPIMS Technique, J. Alloys Compd., 2019, 772, p 112–121. https://doi.org/10.1016/j.jallcom.2018.09.063

W.T.Z.M. Wen, C.Q. Hu, C. Wang, T. An, Y.D. Su, and Q.N. Meng, Effects of Substrate Bias on the Preferred Orientation, Phase Transition and Mechanical Properties for NbN Films Grown by Direct Current Reactive Magnetron Sputtering, J. Appl. Phys., 2008, 104, p 023527.

X.S. Wan, S.S. Zhao, Y. Yang, J. Gong, and C. Sun, Effects of Nitrogen Pressure and Pulse Bias Voltage on the Properties of Cr-N Coatings Deposited by Arc Ion Plating, Surf. Coat. Technol., 2010, 204(11), p 1800–1810. https://doi.org/10.1016/j.surfcoat.2009.11.021

D. Wang and T. Oki, The Morphology and Orientation of Cr-N Films Deposited by Reactive Ion Plating, Thin Solid Films, 1990, 185, p 219–230.

L. Vinet and A. Zhedanov, A ‘Missing’ Family of Classical Orthogonal Polynomials, J. Phys. A Math. Theor., 2011, 44(8), p 127–139. https://doi.org/10.1088/1751-8113/44/8/085201

J.P.A. Immarigeon, G. Van Drunen, and W. Wallace, Hot Working Behaviour of Mar M200 Superalloy Compacts, Superalloys Met. Manuf. Proc. Int. Symp. 3rd Seven Springs, 1976 https://doi.org/10.7449/1976/superalloys_1976_463_472

J. Zhang, L. Li, L. Zhang, S. Zhao, and Q. Guo, Composition Demixing Effect on Cathodic Arc Ion Plating, J. Univ. Sci. Technol. Bei**g Miner. Metall. Mater. (Engl. Ed.), 2006, 13(2), p 125–130. https://doi.org/10.1016/S1005-8850(06)60028-5

H. Elmkhah, T.F. Zhang, A. Abdollah-zadeh, K.H. Kim, and F. Mahboubi, Surface Characteristics for the Ti[Formula presented]Al[Formula presented]N Coatings Deposited by High Power Impulse Magnetron Sputtering Technique at the Different Bias Voltages, J. Alloys Compd., 2016, 688, p 820–827. https://doi.org/10.1016/j.jallcom.2016.07.013

M. Zhang, G. Lin, G. Lu, C. Dong, and K.H. Kim, High-Temperature Oxidation Resistant (Cr, Al)N Films Synthesized Using Pulsed Bias Arc Ion Plating, Appl. Surf. Sci., 2008, 254(22), p 7149–7154. https://doi.org/10.1016/j.apsusc.2008.05.293

F. Aliaj, N. Syla, S. Avdiaj, and T. Dilo, Effect of Bias Voltage on Microstructure and Mechanical Properties of Arc Evaporated (Ti, Al)N Hard Coatings, Bull. Mater. Sci., 2013, 36(3), p 429–435. https://doi.org/10.1007/s12034-013-0479-7

S.A. Choi, S.W. Kim, S.M. Lee, H.T. Kim, and Y.S. Oh, Effect of Working Pressure and Substrate Bias on Phase Formation and Microstructure of Cr-Al-N Coatings, J. Korean Ceram. Soc., 2017, 54(6), p 511–517. https://doi.org/10.4191/kcers.2017.54.6.05

A. Gilewicz, R. Jedrzejewski, P. Myslinski, and B. Warcholinski, Structure, Morphology, and Mechanical Properties of AlCrN Coatings Deposited by Cathodic Arc Evaporation, J. Mater. Eng. Perform., 2019, 28(3), p 1522–1531. https://doi.org/10.1007/s11665-019-03934-2

V.D. Ovcharenko et al., Deposition of Chromium Nitride Coatings Using Vacuum Arc Plasma in Increased Negative Substrate Bias Voltage, Vacuum, 2015, 117, p 27–34. https://doi.org/10.1016/j.vacuum.2015.04.008

M. Huang, G. Lin, Y. Zhao, C. Sun, L. Wen, and C. Dong, Macro-particle Reduction Mechanism in Biased Arc Ion Plating of TiN, Surf. Coat. Technol., 2003, 176(1), p 109–114. https://doi.org/10.1016/S0257-8972(03)00017-3

Y. Zhang, J. Dai, G. Bai, and H. Zhang, Microstructure and Thermal Conductivity of AlN Coating on Cu Substrate Deposited by Arc Ion Plating, Mater. Chem. Phys., 2020, 241(October 2019), p 122374. https://doi.org/10.1016/j.matchemphys.2019.122374

M.H. Guo, Q.M. Wang, J. Gong, C. Sun, R.F. Huang, and L.S. Wen, Oxidation and Hot Corrosion Behavior of Gradient NiCoCrAlYSiB Coatings Deposited by a Combination of Arc Ion Plating and Magnetron Sputtering Techniques, Corros. Sci., 2006, 48(9), p 2750–2764. https://doi.org/10.1016/j.corsci.2005.09.014

Q.M. Wang et al., Hot Corrosion Behavior of AIP NiCoCrAlY(SiB) Coatings on Nickel Base Superalloys, Surf. Coat. Technol., 2004, 186(3), p 389–397. https://doi.org/10.1016/j.surfcoat.2003.12.020

K.J. Tan et al., Oxidation Performance and Interdiffusion Behaviour of two MCrAlY Coatings on a Fourth-Generation Single-Crystal Superalloy, Acta Metall. Sin. (Engl. Lett.), 2022, 35(4), p 679–692. https://doi.org/10.1007/s40195-021-01287-1

P. Patsalas, C. Charitidis, and S. Logothetidis, The Effect of Substrate Temperature and Biasing on the Mechanical Properties and Structure of Sputtered Titanium Nitride Thin Films, Surf. Coat. Technol., 2000, 125(1–3), p 335–340. https://doi.org/10.1016/S0257-8972(99)00606-4

Y. Lv, L. Ji, X. Liu, H. Li, H. Zhou, and J. Chen, Influence of Substrate Bias Voltage on Structure and Properties of the CrAlN Films Deposited by Unbalanced Magnetron Sputtering, Appl. Surf. Sci., 2012, 258(8), p 3864–3870. https://doi.org/10.1016/j.apsusc.2011.12.048

L. Guoqiang, B. **ao, D. Chuang, and W. Lishi, Substrate Temperature Calculation for Pulsed Bias Arc Ion Plating, Surf. Coat. Technol., 2005, 194(2–3), p 325–329. https://doi.org/10.1016/j.surfcoat.2004.07.074

R. Severens, J. Bastiaanssen, and D. Schram, High-Quality a-Si: H Grown at High Rate Using an Expanding Thermal Plasma, Surf. Coat. Technol., 1997, 97(1), p 719–722. https://doi.org/10.1016/S0257-8972

U.K. Wiiala, I.M. Penttinen, A.S. Korhonen, J. Aromaa, and E. Ristolainen, Improved Corrosion Resistance of Physical Vapour Deposition Coated TiN and ZrN, Surf. Coat. Technol., 1990, 41(2), p 191–204. https://doi.org/10.1016/0257-8972(90)90167-B

P.J. Kelly and R.D. Arnell, Magnetron Sputtering: A Review of Recent Developments and Applications, Vacuum, 2000, 56(3), p 159–172. https://doi.org/10.1016/S0042-207X(99)00189-X

M.L. Cedeño-Venté et al., Effect of Graded Bias Voltage on the Microstructure of arc-PVD CrN Films and its Response in Electrochemical & Mechanical Behavior, ar**v, 2018, [Online]. http://arxiv.org/abs/1810.07293.

P.E. Hovsepian, D.B. Lewis, and W.D. Münz, Recent Progress in Large Scale Manufacturing of Multilayer/Superlattice Hard Coatings, Surf. Coat. Technol., 2000, 133–134(November 2019), p 166–175. https://doi.org/10.1016/S0257-8972(00)00959-2

T. Liang, H. Guo, H. Peng, and S. Gong, Cyclic Oxidation Behavior of an EB-PVD CoCrAlY Coating Influenced by Substrate/Coating Interdiffusion, Chin. J. Aeronaut., 2012, 25(5), p 796–803. https://doi.org/10.1016/S1000-9361(11)60447-0

C. Leyens, I.G. Wright, and B.A. Pint, Hot Corrosion of an EB-PVD Thermal-Barrier Coating System at 950 °C, Oxid. Met., 2000, 54, p 401–424.

M.H. Guo et al., The Preparation and Hot Corrosion Resistance of Gradient NiCoCrAlYSiB Coatings, Surf. Coat. Technol., 2006, 200(12–13), p 3942–3949. https://doi.org/10.1016/j.surfcoat.2004.12.005

S.M. Jiang, H.Q. Li, J. Ma, C.Z. Xu, J. Gong, and C. Sun, High Temperature Corrosion Behaviour of a Gradient NiCoCrAlYSi Coating II: Oxidation and Hot Corrosion, Corros. Sci., 2010, 52(7), p 2316–2322. https://doi.org/10.1016/j.corsci.2010.03.032

N. Eliaz, G. Shemesh, and R.M. Latanision, Hot Corrosion in Gas Turbine Components, Eng. Fail. Anal., 2002, 9(1), p 31–43. https://doi.org/10.1016/S1350-6307(00)00035-2

M.P. Brady, I.G. Wright, and B. Gleeson, Alloy Design Strategies for Promoting Protective Oxide-Scale Formation, J. Miner. Met. Mater. Soc., 2000, 52(1), p 16–21. https://doi.org/10.1007/s11837-000-0109-x

W.J. Quadakkers, D. Naumenko, E. Wessel, V. Kochubey, and L. Singheiser, Growth Rates of Alumina Scales on Fe-Cr-Al Alloys, Oxid. Met., 2004, 61(1–2), p 17–37. https://doi.org/10.1023/b:oxid.0000016274.78642.ae

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kheyrodin, M., Mahboubi, F. & Elmkhah, H. The Effect of Negative Bias Voltage on the Microstructure and Hot Corrosion Behavior of Heat-treated NiCoCrAlY Coatings Applied Via the Cathodic Arc Evaporation Physical Vapor Deposition Method. J. of Materi Eng and Perform 33, 283–300 (2024). https://doi.org/10.1007/s11665-023-07943-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-023-07943-0